SOLHAR Energy Solutions & Engineering

SOLHAR – Energy Solutions & Engineering in Kimberley and Botswana

Services Offered by SOLHAR;

⚙️Ceramic Tiling

Extend the life of your equipment with our high-grade ceramic lining solutions. Designed for high-impact and abrasive environments, our tiles—available in various shapes and thicknesses—are expertly installed to protect steel components in mining, power generation, and industrial applications.

🔩 Stainless Steel Fabrication

We supply and fabricate stainless steel components with precision and durability. From sheets and plates to tubing and wire, our corrosion-resistant materials are ideal for construction, manufacturing, and specialized industrial use.

🏗️ Structural & Plate Work

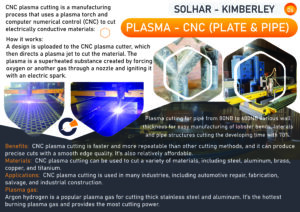

Our 1600m² fabrication facility is equipped to handle complex structural steel and plate work projects. With CNC plasma cutting and overhead crane capabilities, we ensure accurate fitment and efficient on-site installation—backed by rigorous quality control.

📡 Wi-Fi Tower Construction

We manufacture and install radio, Wi-Fi, and CCTV towers up to 21m high. Choose from painted, galvanized, or plated finishes. Our mobile crane ensures safe and efficient installation directly from our Kimberley workshop.

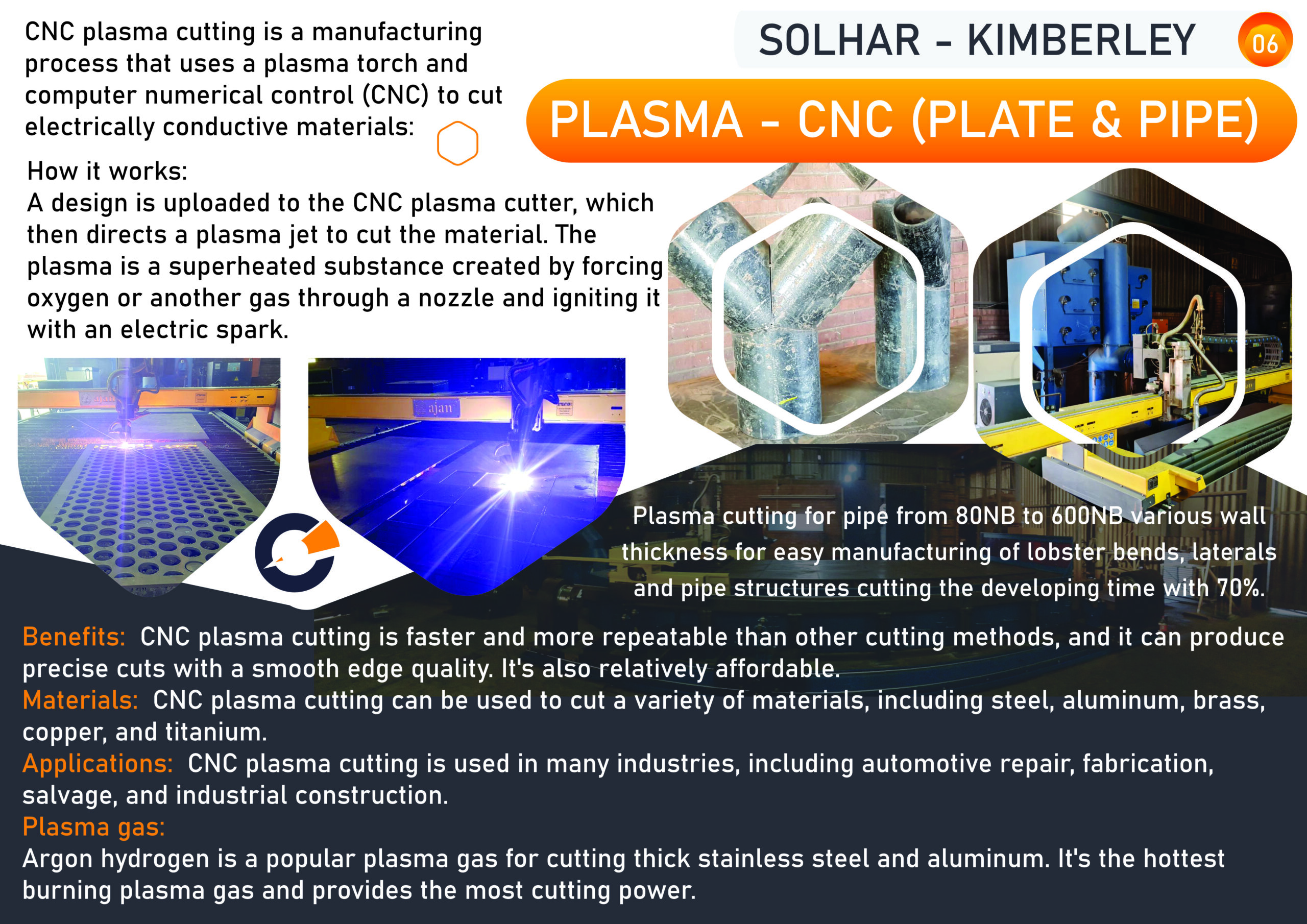

🔧 Pipe Work & CNC Cutting

As the Northern Cape’s only 3D CNC pipe cutting facility, we deliver precision-fabricated spool pieces, tee joints, and lobster bends. Our cutting range spans 50NB to 600NB, ensuring fast turnaround and cost-effective solutions.

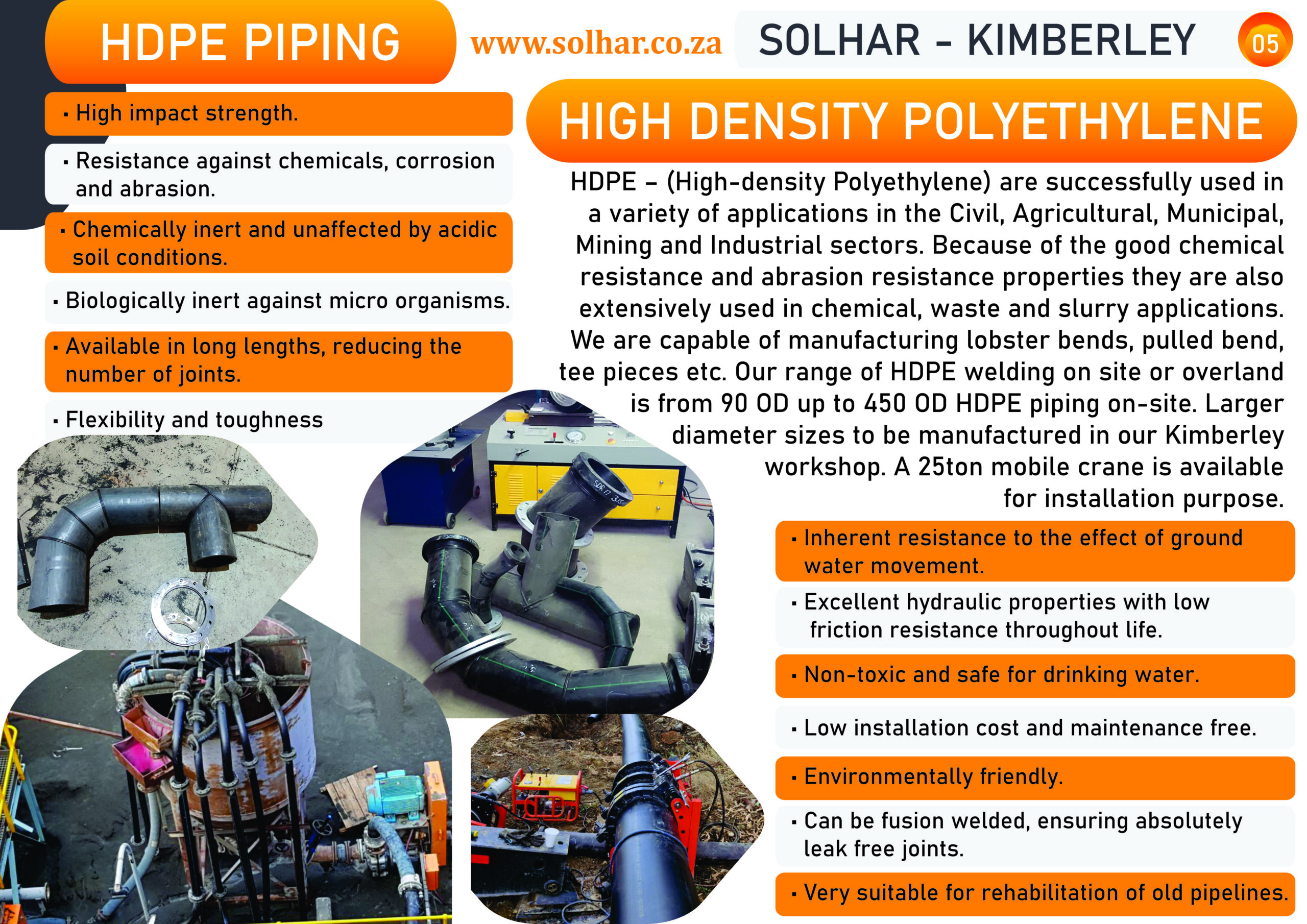

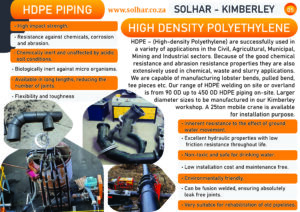

🛠️ HDPE Piping

We supply and weld HDPE piping for civil, mining, and industrial sectors. With on-site and workshop capabilities, our range covers 90 OD to 450 OD, including custom bends and fittings for slurry, chemical, and waste applications.

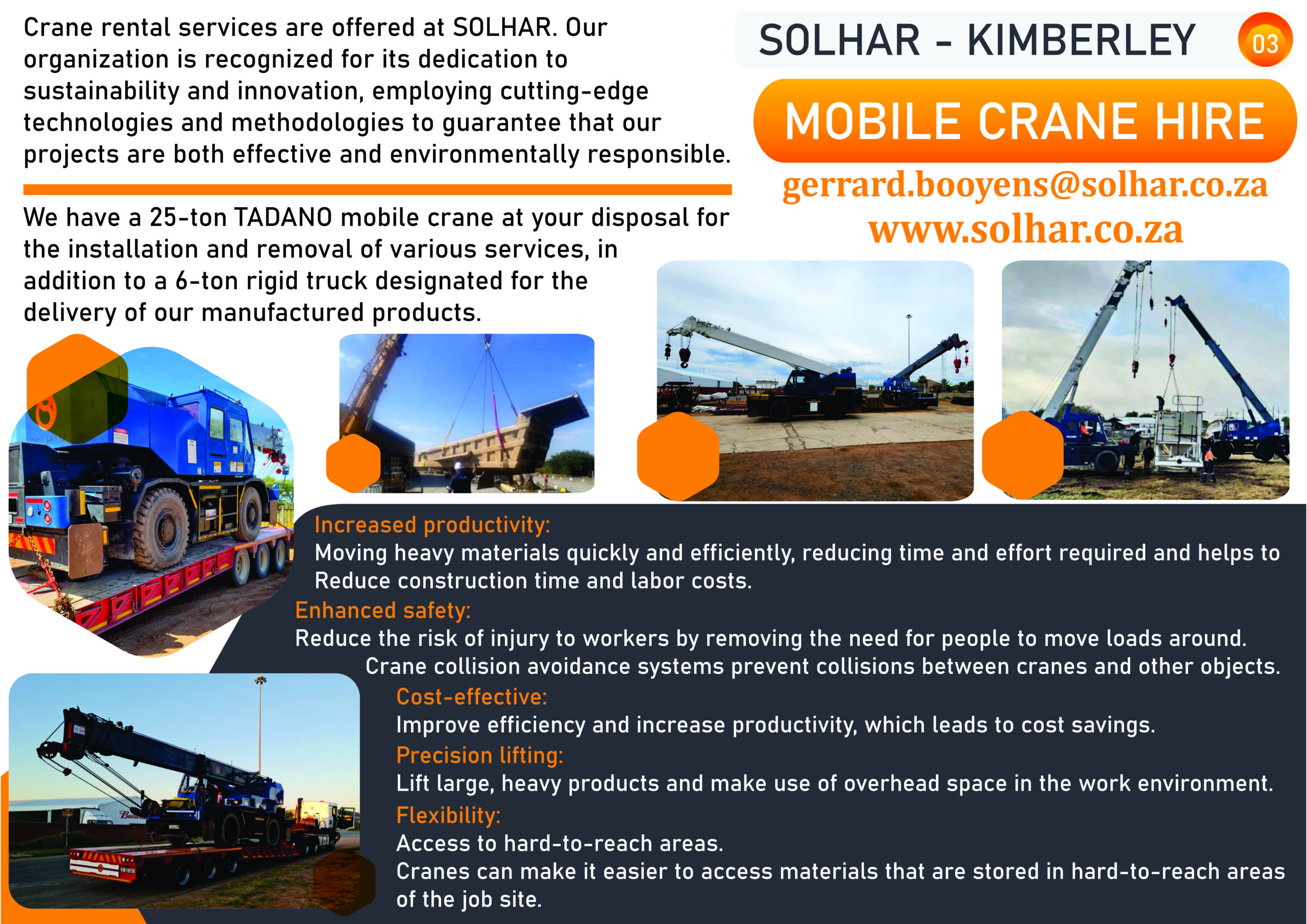

🚚 Crane Hire

Our 25-ton TADANO mobile crane and 6-ton rigid truck are available for lifting, installation, and delivery of fabricated components—ensuring seamless logistics for your project.

🛡️ Corrosion Protection

We prepare steel surfaces to Swedish SA 2.5 standards using advanced sandblasting techniques. As Kimberley’s STONCOR distributor, we offer premium coatings like Carboline, Alumanation, and Rust-Oleum for long-lasting protection.

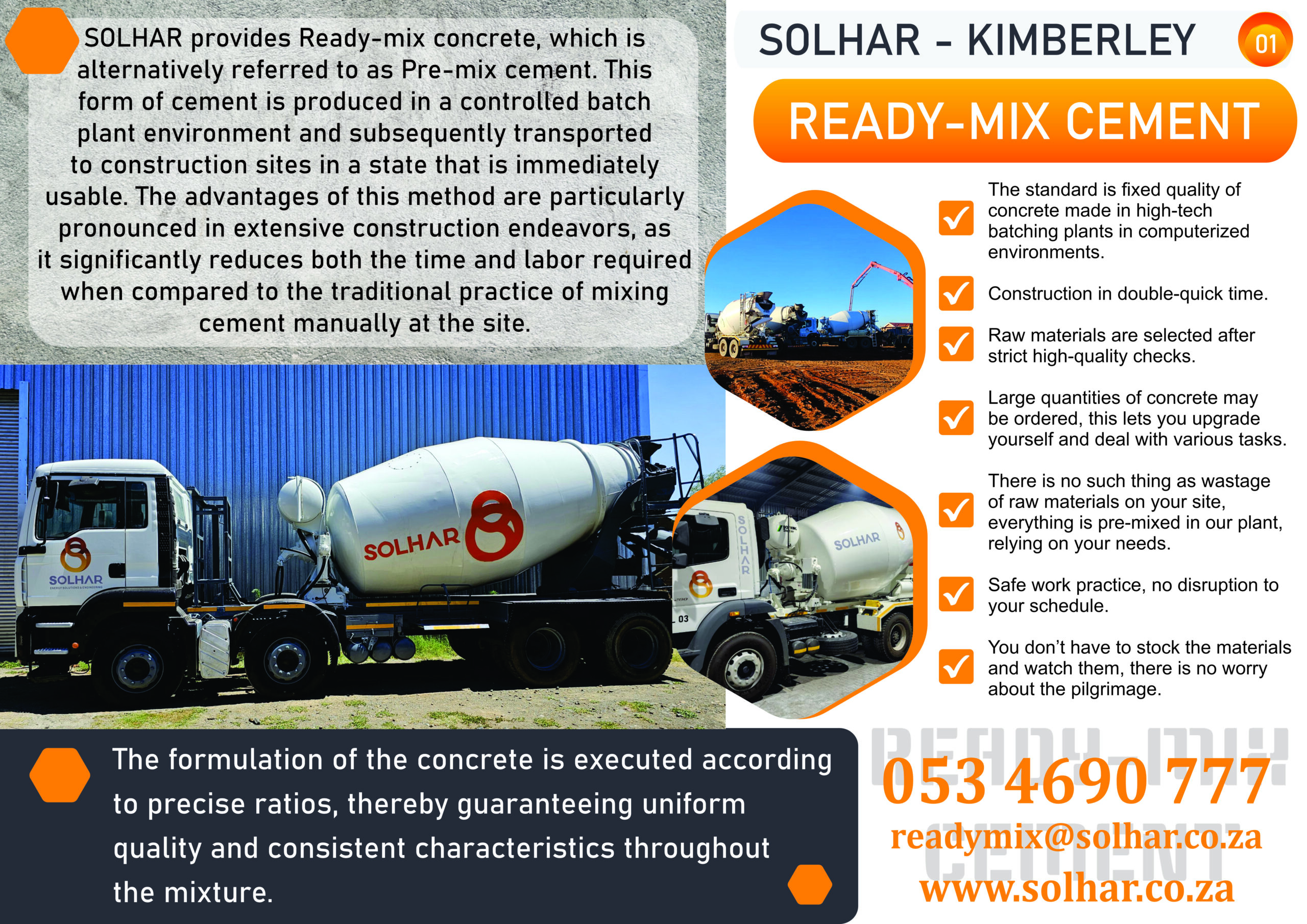

🧱 Ready-Mix Concrete

Our ready-mix concrete is batched to precise specifications and delivered in a ready-to-use form. Ideal for large-scale construction, it ensures consistent quality, reduces labor, and speeds up project timelines.

🔥 Thermal Spray Painting

Protect your components with our thermal spray coatings. This metallurgically cold process offers superior resistance to wear, corrosion, and heat—ideal for industrial repair and preventative maintenance.

Structural Steel

Engineered for strength, precision, and reliability—our structural steel solutions form the backbone of buildings and heavy-duty infrastructure. We fabricate and install steel components that meet exacting load-bearing and environmental demands. Through advanced heat treatment and alloying, we tailor each element to your project’s specifications, ensuring long-term performance and compliance with engineering standards.

⛏️ Mining-Grade Steel Plasma Cutting & Liner Solutions

Maximize your mining operation’s efficiency with precision-cut steel components tailored to your specs. Our advanced nesting software and plasma cutting technology ensure optimal material usage—whether you supply the steel or we source it for you.

We offer high-performance steel liners up to 40mm thick, built with HARDOX 500/650 for extreme wear resistance in the harshest environments. Every cut is made to your design, enabling immediate assembly and streamlining your fabrication line.

Quality and service drive us—on-time delivery is not a promise, it’s our standard.

⚙️ Advanced Wear-Resistant Lining for Mining & Plant Systems

At SOLHAR, we specialize in lining systems that enhance the mechanical, pneumatic, and hydraulic conveyance of highly abrasive materials. Based in Kimberley, our CNC plasma division ensures precision cutting and customization to meet your plant’s exact requirements.

We offer a full spectrum of wear-resistant options:

- High Brinell strength plates with up to 60 HRC / 700 HBW for extreme durability

- Overlay wear plates with arc-welded coatings for superior abrasion resistance

- Hi-wear round bars (Ø40–100 mm, up to 5000 mm long) with excellent bendability and weldability

- Rubber-back liners combining polyurethane/rubber with metal backing for steel chute installations

GHAAP Engineering and Field Services in Daniëlskuil

SOLHAR and GHAAP have collaborated to support mines in South Africa in maintaining operational efficiency by providing a comprehensive range of services applicable to incoming projects.

We have achieved several successful installations to date and are eager to secure additional contracts to strengthen this mutually beneficial partnership.

- All

- BAOBAB SAFETY TREE

- Botswana Stage Tank

- BULL RUN 2024

- CNC Plasma Cutting

- Dozer Blade - Idwala Lime Mine

- ESKOM BUILDING

- GHAAP

- High Wear Plate Liners

- JOINTSHAFT

- KIMBERLEY WATER SHUTDOWNS

- PCCU PROJECT

- Plate Work

- PROJECTS

- Ready-Mix Concrete

- Ready-Mix Concrete Cement Projects

- Refurbishment

- Riverton Clarifier Refurbishment

- SOLHAR Botswana

- SOLHAR Civil Projects

- SOLHAR Performance Evaluation

- Stainless Steel

- Stockpile Crusher

- Structural Steel

- Thermal Spray Painting

- VERMEULENS

- Wi-Fi Towers

- Wingwalls

We strive at all times to ensure that our Company meets the laid down legislative and labour related requirements and that we address the national challenges of unemployment, ownership and sustainable development. We take pride in providing the highest level of efficient and effective workmanship with high level of service at all times.

Our core business is to venture into the mining industry through a carefully scheduled plan with firm guidelines, assisted by the construction and managing experience in this field.

Our activities will be directed at carefully selected projects, which can provide significant growth and sustainability to our clients. We are also penetrating the Solar Energy as well as the Building industry to aid in the demand for generation of renewable energy we are facing in this country.

Specialized Services and Customized Manufacturing & Installation of;

Ceramic Tiling, CNC Plasma Cutting, Corrosion Protection, HDPE – High Density Polyethylene, High Wear Plate Liners, Pipe Work Plate Work, Ready-Mix Concrete delivered to you, Complete SMPP (Structural, Mechanical, Plate Work and Piping), Stainless Steel, Structural Steel, Thermal Spray Painting and Wi-Fi Towers. We also have cranes to assist us in our big jobs.

We take pride in providing the highest level of efficient and effective workmanship with high level of service at all times.

Why Structural Steel Pricing Varies So Widely

In today’s market, not all steel fabrication quotes are created equal. While some contractors focus solely on offering the lowest price, reputable companies like SOLHAR prioritize quality, safety, and long-term value.

In today’s competitive market, structural steel quotations can vary dramatically. At SOLHAR, we believe in transparency and quality—and we want to help you understand why our pricing reflects long-term value, not just short-term savings.

Transforming the VERMEULENS N12 Building: A Façade to Remember

How Solhar Delivered a Standout Architectural Statement Under Pressure

Every so often, an opportunity comes along that both excites and challenges your team in equal measure. At Solhar, we recently had the privilege to embark on such a project: the design and installation of a brand-new façade for the impressive VERMEULENS N12 building.

KEW Foundries – Supplier performance evaluation for the period (July to December 2024)

We are known for our commitment to...

Ready Mix Concrete at VERMEULENS Brand New N12 Business Park Development in Kimberley

SOLHAR READYMIX is proud to announce that it has been awarded the prestigious contract to supply high-quality READYMIX CONCRETE for VERMEULENS’ exciting new N12 business park development.

As a leading provider of concrete solutions, SOLHAR READYMIX was selected for this project due to its proven track record of delivering superior products and exceptional service. The company’s state-of-the-art production facilities, experienced team of professionals, and unwavering commitment to quality assurance were key factors in securing this significant contract.

KEW Foundries – Supplier performance evaluation for the period (January to June 2024)

Suppliers of services and products to KEW Foundries forms an integral part of our Quality Management System and ability to meet the expectations of our customers. Supplier performance is measured based on the number of orders placed on the supplier and the ability of the supplier to deliver goods or services as per the order.

Dozer Blade Project – Removable Wear Liners done for Idwala Lime mine

IDWALA LIME approached us for a solution to address the wear issues of their dozer blade during operation. In response, SOLHAR developed a removable wear liner that can be bolted onto the bottom of the dozer blade, allowing for quick and easy replacement within a single day.

Environmental Responsibility Statement At SOLHAR, we recognize the importance of responsible environmental stewardship across all aspects of our operations. We are committed to managing our activities in a manner that minimizes environmental impact—adopting best practices to reduce waste, optimize resource use, and maintain compliance with industry standards.

Our team actively monitors environmental performance, reviews internal policies regularly, and ensures the responsible disposal of all materials related to civil and steel works, fabrication, and mining operations. This approach reflects our ongoing dedication to sustainable engineering and ethical industrial conduct.

Our Kimberley Branch is situated at 8 Hendrik van der Bijl, Kimdustria, Kimberley, 8301, Northern Cape, South Africa

Solhar Energy Solutions & Engineering Contacts:

GERRARD BOOYENS

082 551 4082

gerrard.booyens@solhar.co.za

KEVIN HARDING - Ready-Mix

083 256 9975

kevin.harding@solhar.co.za

BRIAN DANIELS

082 481 0616

brian.daniels@solhar.co.za

Solhar Energy Solutions & Engineering Botswana Contact:

ROY DE BRUIN

+26771660127

roy.debruin@solhar.co.za

CONTACT US;

Brave men are not born! They are molded. SOLHAR constantly thrive to achieve the set goals monthly and we maintain our identity in what we stand for. If we do not stand for something we might fall for anything. May GOD always stay our protector in whatever project we complete, big or small. To HIM alone the glory and honor - Hallelujah

Men tend to lose their identity in these trying times. We are identified as hard working men taking ownership and responsibility as good, loyal GOD fearing men for our households! BE THE MAN everyone talks about. Stand out in the crowd. Believe and NEVER forget your role and responsibility.

Deliver service. Something we tend to be dislodged from in society in having a basic right to services rendered around us. If GOD stops to deliver the sun, moon, and stars on time we are done with and therefore we strive to keep our focus on delivery of service to our customers.